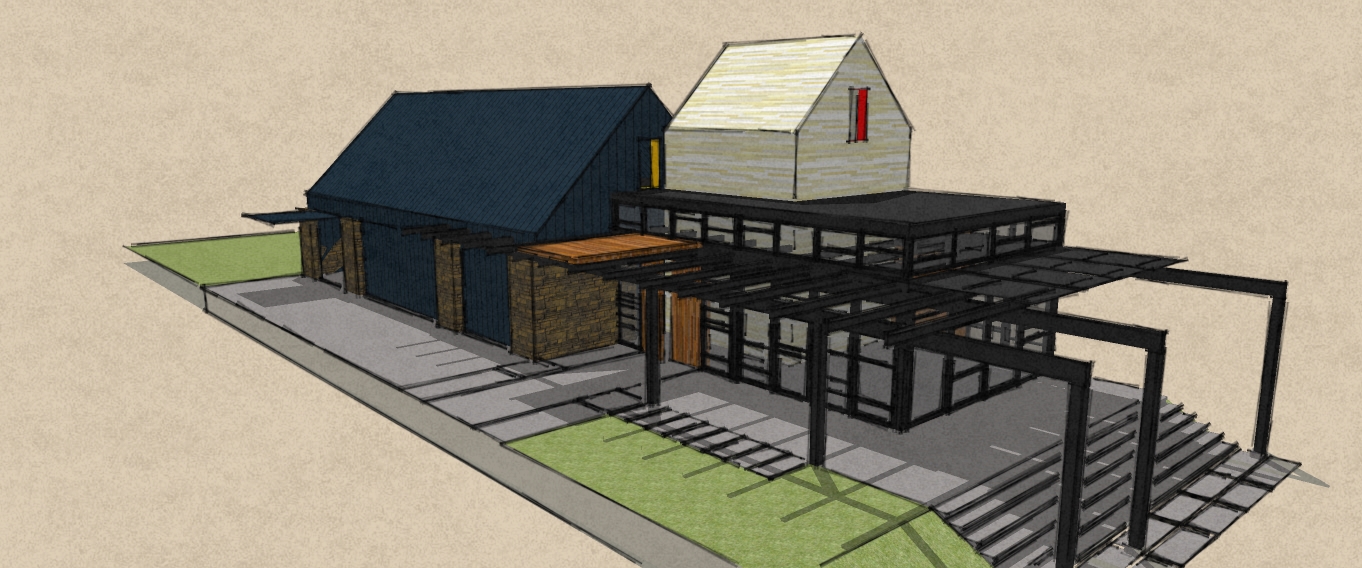

Even the least desirable properties are now being rebuilt.

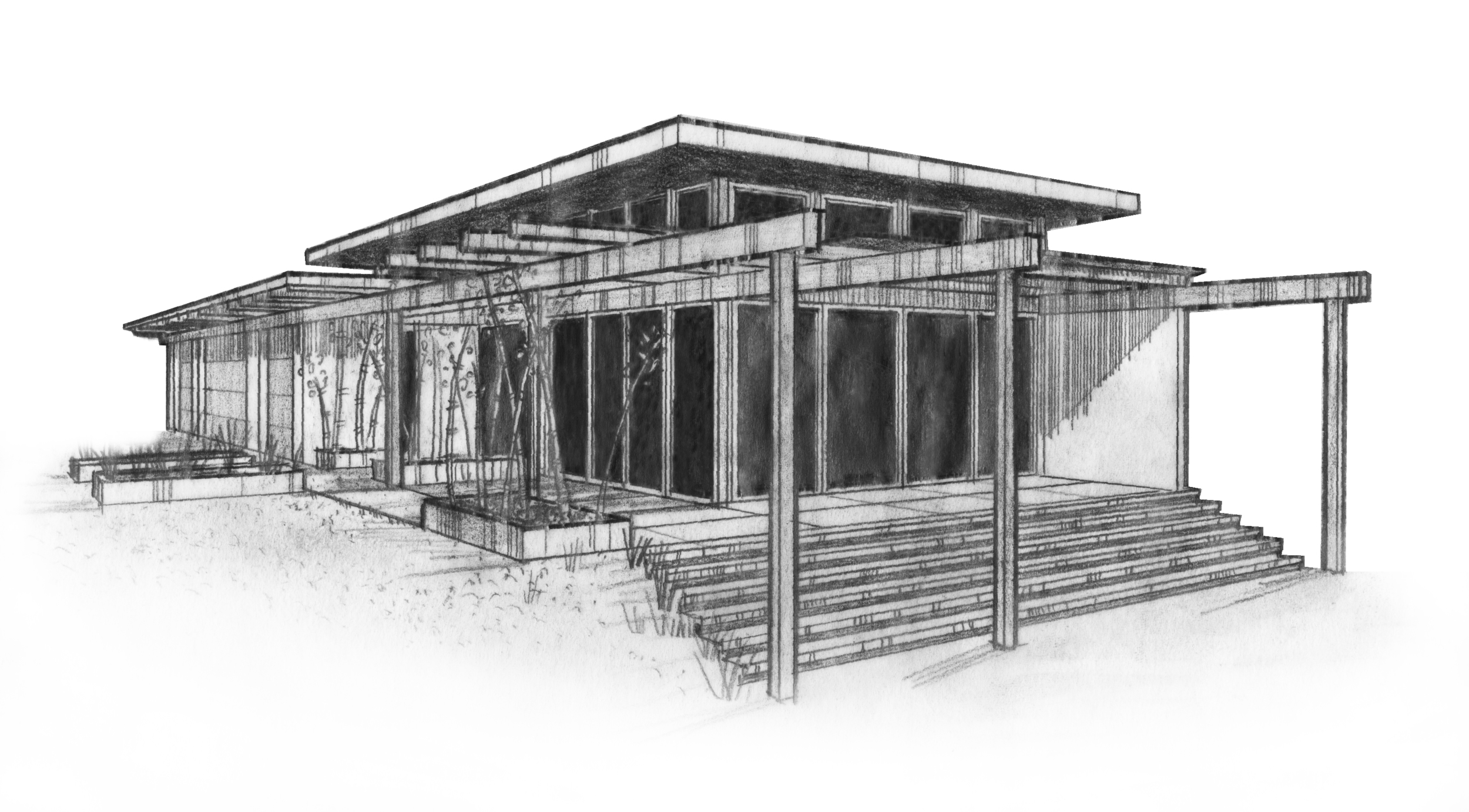

Are you new to Seattle? Yes, you are. Whether you relocated from somewhere else (like most of us) or have lived in Seattle your whole life, you are, in fact, new to Seattle. Seattle is one of America's fastest growing big cities, so even Seattle natives don't recognize the city anymore. The city has changed so rapidly due to the successes of big businesses like Microsoft, Boeing, and Amazon, as well as so many other tech companies. This brings tons of money to Seattle, and its residents are spending it on construction projects both for work and home. We see cranes all across the city erecting high rise buildings, and residential architects, like myself, see a boom in our project list. The entrepreneurial spirit in Seattle brings an innovative, forward-thinking mindset to the economy, as well as, to the architecture that shapes the city.

When the economy tanks, the construction stops, and architects look for work. Businesses stop growing, they stop developing, the construction stops, and people stop hiring architects to design glamorous projects. Instead of large new construction projects, homeowners try to save money by remodeling and adding onto their homes. Around 2010, many of the builders and architects out there were not setup for this smaller-scale type of work since they had too much overhead in simply running their businesses, and they also were living in a "rock star" sort of paradigm of project typologies.

After living in a booming Seattle economy for just a few years, its economic downturn created an environment that was familiar to me. I was an implant from the Ohio "rust belt," an area of the country between Cleveland and Pittsburgh devastated from the negative effects of the failing steel and automotive industries. My hometown of Youngstown, Ohio was trying to figure out how to shrink. I would participate in community service design events to figure out what to do with the land leftover from the demolition of entire neighborhoods. You can only build (and maintain) so many parks, especially with a dwindling population without jobs. Seeking better opportunities, I relocated to Seattle with my blue collar mindset that was completely opposite of the booming Seattle economy I was initially immersed in. Even when designing for very high profile clientele, my inherent frugality enabled my design and construction methodologies to set me apart from my colleagues. Clients and builders took notice. Then the Seattle economy tanked. This was my opportunity to entertain projects that larger companies with less passion and more overhead could not take on. Builders and clients knew me as a guy who could get the job done well in an adverse environment.

Now that the economy is booming again, things are just that much easier for me. I never slowed down when the economy did, and I also never sped up when the economy did (by choice). A steady stream of work has been constant. That is part luck, part skill, and part choice: don't bite off more than you can chew. A lot of companies get greedy and grow too fast. I am quite happy running a small business that I can intimately manage and play a key role in every single detail. That's why I started: I like designing buildings. Once a business grows too big, overhead expenses grow, office tasks become a burden, and the fun parts of the job get outsourced to staff. I have no interest in that. I like designing cool buildings. I like working with clients. I like outsmarting the building department for my clients' benefit. There's no end in sight for me. James, my financial guy, asked me what I want to do when I retire. I said, I want to be an architect, and that's just what I'll do. The opportunities to design awesome architecture in Seattle are just too prevalent for me to ever stop. I suppose it's an addiction for me.

If you’d like to learn more about our design process, visit www.josharch.com/process, and if you’d like to get us started on your project with a feasibility report, please visit www.josharch.com/help